Gas Detection Location Design

Gas Detection Systems are required to protect people and assets wherever hazardous situations exist due to the presence of flammable or toxic gas. Health & Safety regulations (Health and Safety at Work Act, DSEAR, COMAH etc.) clearly place the duty on employers to protect people from the risks related to dangerous substances and potentially explosive atmospheres. An effective Gas Detection System protects people and companies and should be managed as part of an ongoing management lifecycle. Proeon Systems can support this process by providing a range of technical safety services to review and design such systems.

When does a company need a Gas Detection Survey?

New Systems: When a risk assessment determines a requirement for a Gas Detection System, the Gas Detection Survey will provide the confidence that the field detectors are located in the correct positions to provide the required coverage.

System Upgrades: When systems are upgraded or significantly changed regulators recommend a review of the design to ensure the system is adequate.

Changes in Process or Building: When any change occurs within a process or building, risk assessments should be updated.

Periodic Reviews: Systems should be subject to periodic reviews. COMAH sites require five-year reviews due to their hazardous nature. The Gas Detection System is often a safety related system and should be reviewed on a regular and documented basis.

What is a Gas Detection Survey?

A Gas Detection Survey will confirm the correct gas detector locations to address the identified risks and provide supporting documentation to back up the risk assessments.

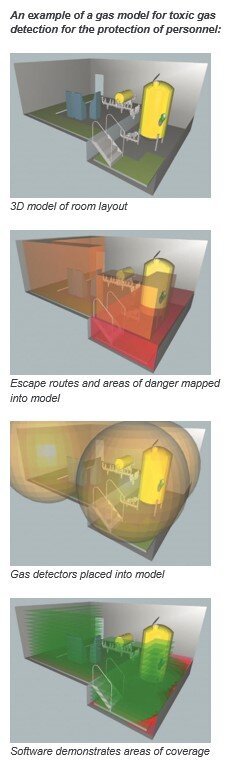

Supported by specialist 3D mapping software, Proeon prepare a report that provides:

Details of the risks identified by the end user including; descriptive of the area of risk, proposed detection zones, means of escape and mitigation

Graphical representation of the units’ area or building

Graphical representation of the risk

Graphical representation of the detection coverage

Equipment location diagrams

Percentages of coverage

Recommendations for installation

Observations regarding the installation that fall outside the scope of the report, that may have an impact on means of escape and transmission of gases.

An effective gas detection system should:

Detect potentially hazardous releases or accumulations of gas

Initiate alarms to alert personnel to act

Begin executive action to reduce escalation and mitigate the risk

To confirm this the gas detection system requires these key components:

Risk Assessment: Risk assessments are part of every process. If your company has identified a risk from gas then a competent person should advise how to manage the risk.

Mapping & Detection Selection: Correct detector location ensures the system can detect the gas in time for appropriate action. A competent person with experience and training can provide suitable and sufficient gas detection mapping.

Design & Specification: Choosing the operating principles detectors and control panel to reflect the Risk Assessment and the Executive Actions required.

Installation and Service: Correct installation to the specification is evident. A suitable inspection and service regime demonstrates active management.

Periodic Review: Safety related systems should be reviewed ‘periodically’ as part of the lifecycle management. Reviews should consider system design, updated technology, availability, and personnel.

What types of Gas Detection Survey does your company need?

Office Based Design Review

Proeon Systems offer an office- based design process to provide Gas Detector Location Design. Once Proeon has been supplied with accurate layout and GA drawings together with details of the perceived risk and appropriate risk assessments, we will provide a report detailing how best to protect the occupants and / or production asset. Based on the information provided, the report will include graphical representations, percentages of coverage, and the equipment locations. The office- based design is ideal for projects still in the design stage or undergoing construction.

Gas Detection Survey

The Gas Detection Survey offers a trained Proeon Engineer to attend the site; to meet with the end user, agree risk management strategies, survey the building, processes and storage areas, and confirm fixed life safety systems. The report will include graphical representations, percentages of coverage, and the equipment locations (based on the information gathered from the survey). The Gas Detection Survey is aimed at new Gas Detection Systems being installed or older systems that are being upgraded.

Gas Detection System Review

The Gas Detection System Review is a comprehensive offering from Proeon Systems that includes; a document review of drawings, safety requirement specifications, and previous risk assessments. During the site meeting and survey the trained Proeon Engineer will survey the building, processes and storage areas together with fixed life safety systems (Fire Alarm, Emergency Lighting, Means of Escape, etc.). The completed report will include graphical representations, percentages of coverage, and the equipment locations (based on the information gathered from the survey) together with a recommended action plan.

The Role of Responsible Person

Carrying out suitable and sufficient risk assessments and ensuring that appropriate measures are taken to protect the occupants of your business is a moral and legal responsibility that must be taken seriously. In many cases the Responsible Person (the person who is in control of the building) will not have the training, skills or experience to design or review the Gas Detection Locations as required by HSE (*Ref:1). Proeon provide personnel with the expertise, specialist training, experience and knowledge to provide third party assessment and supporting documentation. Each Gas Detection Survey is undertaken and supervised by fully qualified staff to ensure that the design is correct and appropriate, protects personnel and supports the Responsible Person with their obligations.

Additional Technical Safety Services

Proeon provides a range of technical safety services to augment the Gas Detection Survey activities that includes:

Industrial Fire Risk Assessments

Review and development of machinery, process control and safety systems including shutdown and Fire / Gas Detection and Alarm Systems

Machinery safety review

Development of proof test procedures

Escape routes and signage review

Input to HAZID / HAZOP activities

Risk assessment review and development

Functional Safety Services including SIL assignment and SIL verification activities

Human factors including control room design and ergonomics

Electrical safety reviews

Emergency response facilities and procedures

Review and development of plant wide telecoms and communications systems

Proeon draws on world leading engineering expertise to manage your project, from concept design, development and manufacture of complete packages, through to providing support, installation and commissioning.

Why not contact us to discuss your specific requirements and how we can support you today? T: +44(0)1953 859 110

*Ref: 1 The Management of Health and Safety at Work Regulations 1999